For a smooth process.

For maximum efficiency.

Für maximum availability.

Our vacuum evaporators and systems are a valuable investment. More than 2/3 of the systems that KMU LOFT Cleanwater has sold in the last 30 years are still in use. To ensure smooth operation for you, our service team supports you with the necessary products and services.

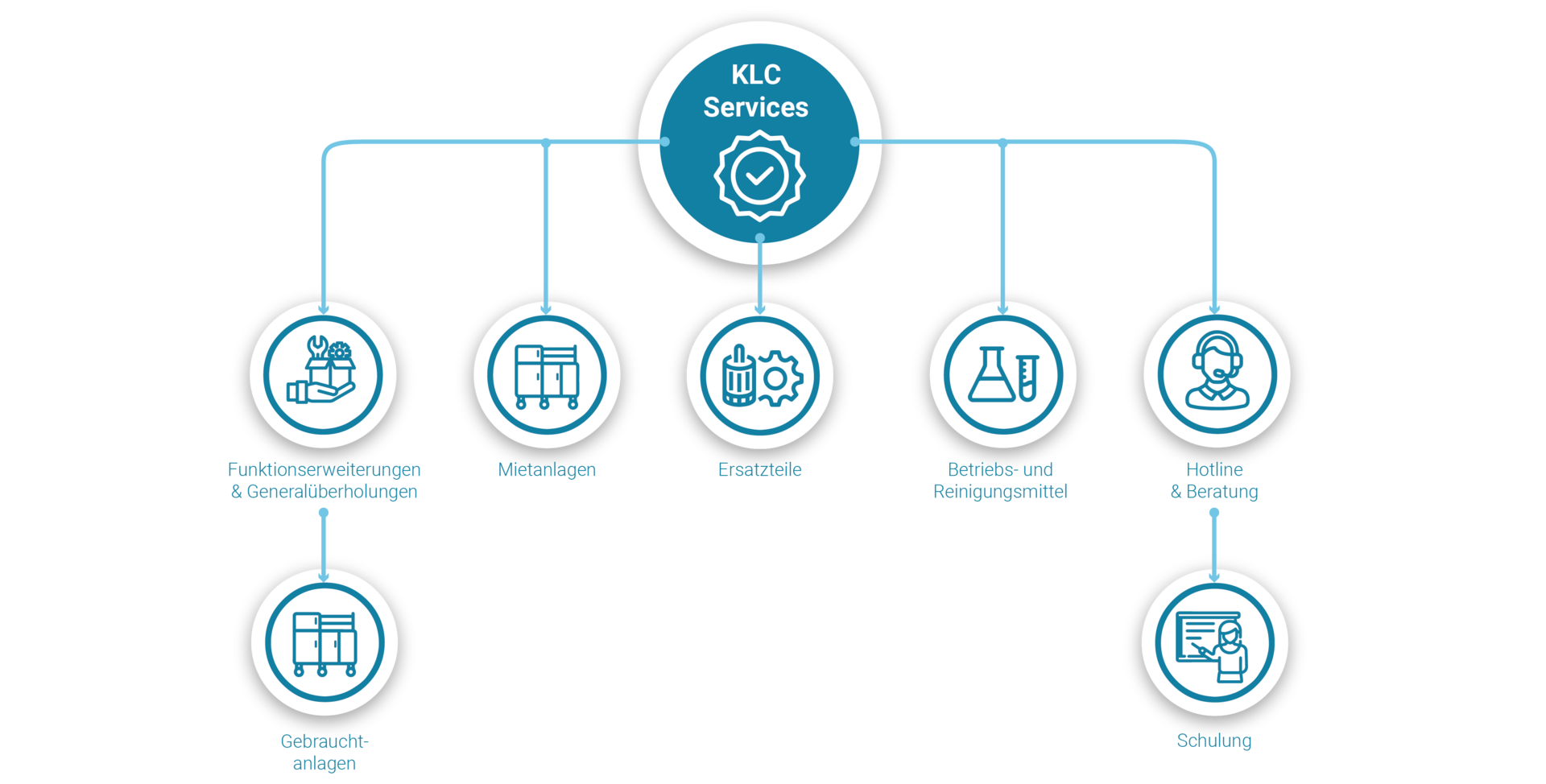

Our KLC services for your vacuum evaporator

KMU LOFT Cleanwater is proud of the long service life of its vacuum evaporators and treatment systems. The systems work largely autonomously and have few wearing parts. With the right settings and regular maintenance, the systems perform well for years, even if the process water changes. The KLC service supports you: as a pioneer of Industry 4.0, we can monitor the operation and all key parameters of the systems remotely. This reduces costs and increases the availability of the systems.

We are there for the customer

Our service team looks after your systems throughout their entire serivce life.

We keep an eye on operating costs

The daily maintenance effort for the KMU LOFT Cleanwater vacuum evaporators is very low and amounts to a maximum of half an hour. Many processes run automatically.

The vacuum evaporator also compares favourably with other wastewater treatment processes in terms of operating costs when optimised. Our service team will support and advise you in optimising your operating costs. If used correctly, the costs for energy, operating and cleaning materials and, above all, maintenance are low. KMU LOFT Cleanwater trains the operating personnel, carries out regular maintenance and provides support with spare and wear parts.

System availability under control

Our vacuum evaporators are largely automated. Thanks to the few moving parts and the programmes adapted to the process water, the control system regulates system operation largely autonomously. KMU LOFT Cleanwater sets the optimum parameters for the best results and optimum costs and can monitor them regularly at the customer's request.Advantages of vacuum evaporation

Sustainable conservation of resources through efficient wastewater treatment

Our KLC service

The experts in our consulting team have many years of experience in the operation of vacuum evaporators and systems. They will help you with any questions that arise at short notice and work with you to find the optimum solution. Depending on customer requirements, we work with service level agreements or on call.

The service technicians from KMU LOFT Cleanwater go on site worldwide. They advise customers directly on the systems, check all settings and components and carry out all necessary work directly.

KMU LOFT operating resources

Ensure the efficiency and availability of your system and benefit from the many years of experience of the KMU LOFT Cleanwater (KLC) application specialists!

With our cleaners, defoamers and additives, you can achieve maximum process stability and long-term operational reliability for your vacuum evaporator. Take advantage of the expertise of KLC's two in-house application laboratories to achieve maximum system efficiency with operating fluids that are precisely tailored to your application.

Operating resources

Download the most important information on our operating resources here.

KLC Cleaners

Whether based on sulphur, phosphorus or citric acid, our KLC speciality cleaners, which are constantly being developed in our own application laboratories, guarantee cleaning effectiveness and process stability. All cleaners can be used several times!

KLC Defoamer

When vaporising highly foaming media, defoamers specially adapted to your application are also used to achieve the desired process stability. You benefit from over 25 years of experience of our KLC application specialists.

KLC Additives

Our additives, developed in innovative test work, prevent crust formation in the shell-and-tube heat exchanger or corrosion in the vacuum pump, even with extremely aggressive media, thus ensuring the operational reliability and service life of your vacuum evaporator.

Poison emergency call

24/7 world-wide

+49 (0) 6132 - 84463

![[Translate to Englisch:]](/fileadmin/user_upload/kmu_header_navigation_produkte.jpg)

![[Translate to Englisch:]](/fileadmin/user_upload/kmu-loft_loesungen_navigation5.jpg)

![[Translate to Englisch:]](/fileadmin/user_upload/kmu_header_navigation_industrien.jpg)

![[Translate to Englisch:]](/fileadmin/user_upload/kmu_header_navigation_service.jpg)

![[Translate to Englisch:]](/fileadmin/user_upload/kmu_header_navigation_ueberuns_final.jpg)

![[Translate to Englisch:]](/fileadmin/user_upload/kmu_header_navigation_nachhaltigkeit-og.jpg)