Automotive/

Aerospace

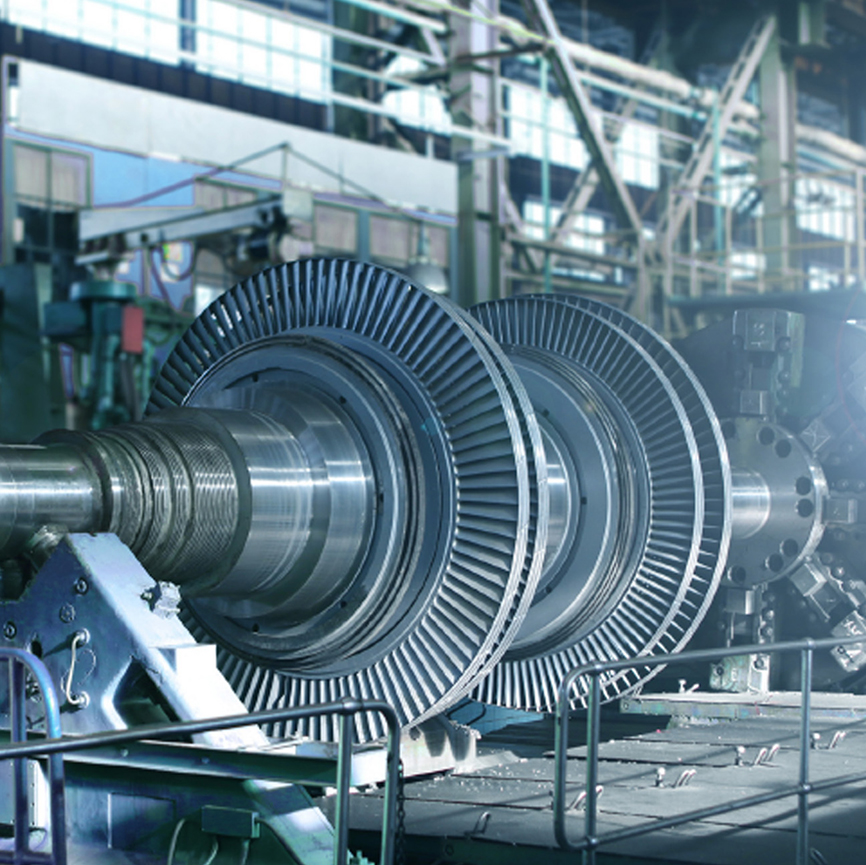

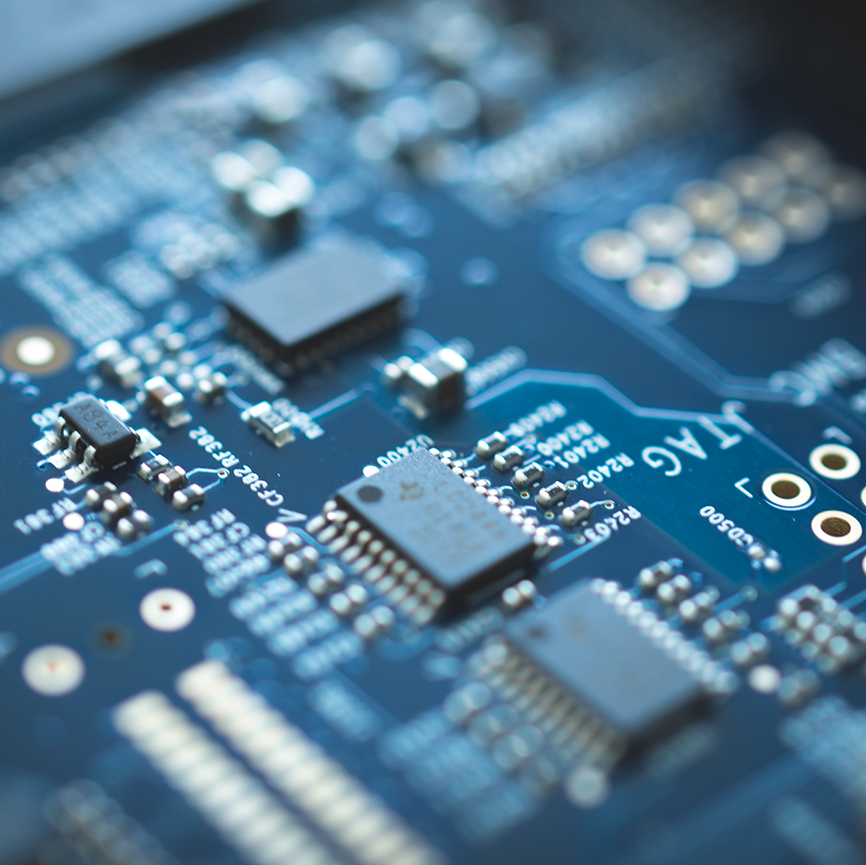

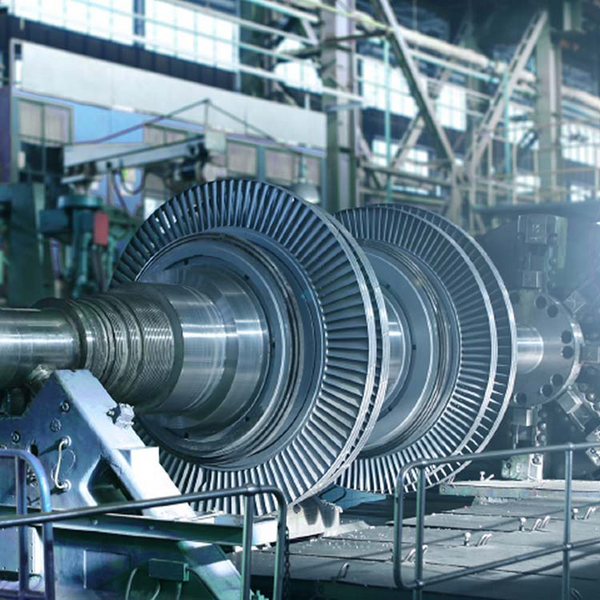

Machinery and plant engineering

In mechanical and plant engineering, process water is generated in a wide variety of production processes, for example in the mechanical machining of machine and plant components, in die casting or in electroplating.

Typical process water types:

- emulsions (coolants and lubricants)

- release agents (aluminum die casting)

- wash waters, rinsing and active baths

- electroplating, hardening and grinding waters

- rinsing water from crack detection systems

To the industries

Advantages of process water treatment

With KMU LOFT's evaporator technology, process waters can be purified to produce up to 99% recyclable distillate. The distillate can be fed back into the production process, especially in washing and cleaning applications, and thus reused. Recirculation of make-up water for emulsion and release agent is also possible.

KMU LOFT Cleanwater develops a complete solution tailored to processes and process water.

![[Translate to Englisch:]](/fileadmin/user_upload/kmu_header_navigation_produkte.jpg)

![[Translate to Englisch:]](/fileadmin/user_upload/kmu-loft_loesungen_navigation5.jpg)

![[Translate to Englisch:]](/fileadmin/user_upload/kmu_header_navigation_industrien.jpg)

![[Translate to Englisch:]](/fileadmin/user_upload/kmu_header_navigation_service.jpg)

![[Translate to Englisch:]](/fileadmin/user_upload/kmu_header_navigation_ueberuns_final.jpg)

![[Translate to Englisch:]](/fileadmin/user_upload/kmu_header_navigation_nachhaltigkeit-og.jpg)